What are Advantages of Custom Optical Windows?

Optical windows are critical components used in various applications, from lasers and cameras to scientific instruments and aerospace equipment. These transparent elements allow light to pass through while protecting sensitive devices from external elements. While standard optical windows serve many purposes, there are instances where off-the-shelf solutions might not meet specific requirements. That's where custom optical windows come into play, offering tailored solutions for your precision needs.

Custom windows are designed and manufactured to meet precise specifications that may not be readily available in standard options. These windows are crafted with exceptional precision, ensuring that they align perfectly with the intended application's demands. By working closely with optical engineers and manufacturers, customers can get optical windows optimized for their unique requirements, including size, shape, material, coatings, and performance characteristics.

2. Advantages of Custom Optical Windows

A. Tailored Performance

One of the primary advantages of opting for custom optical windows is the ability to achieve tailored performance. Off-the-shelf windows might not deliver the desired optical clarity, transmission rates, or wavelength range required for specialized applications. Custom windows can be optimized to enhance performance, ensuring that they precisely meet the needs of the system.

B. Material Selection

Custom optical windows provide the freedom to select the most suitable material for the application. Different materials offer distinct advantages, such as high transmission rates, thermal resistance, or chemical durability. By choosing the right material, customers can enhance the overall efficiency and longevity of their optical systems.

C. Coating Options

The optical properties of windows can be further improved through specialized coatings. Custom optical windows allow customers to select from a wide range of coatings, including anti-reflective coatings, dichroic coatings, or protective coatings. These coatings can enhance light transmission, reduce glare, and protect against environmental factors.

D. Complex Geometries

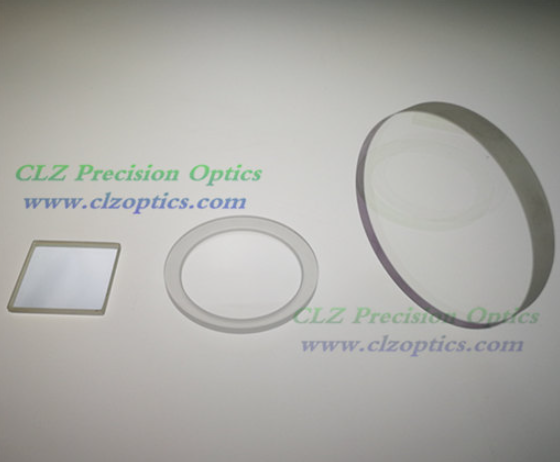

Certain applications require silicon optical windows with non-standard shapes and complex geometries. Custom manufacturing enables the production of windows in unique shapes, such as circular, elliptical, rectangular, or even irregular forms. This flexibility ensures seamless integration into the target device.

- Previous: What Are Seismic Sensors?

- Next: Choosing an IMU: FOG vs MEMS IMUs

- 0